SCOPE of WORK

|

|

PROJECT NATURE

Dissemination of RFCS project results is recommended in the RFCS program. The overall annual potential benefit for the Coal and Steel Sectors would amount to roughly 700 M€.

The proposed dissemination project is directly related to Article 17 of the council decision 2008/376/EC, “RTD and the utilisation of steel”, “Accompanying measures”, where it is stated that “Accompanying measures shall relate to the promotion of the use of knowledge gained or to the organisation of dedicated workshops or conferences in connection with projects or priorities of the Research Programme”.

MOTIVATION

In the framework of the European Steel research programmes (ECSC and RFCS) many projects have been carried out on the formation of cracks in continuous casting, aiming at facing this occurrence and its harmful impact on surface and internal product quality.

As an example, when processing semis with inadequate surface quality, cost due to rejection at the finishing stage rises on average to 275 €/T, (due to rolling, heat treatments, finishing, redressing, non-accomplished deadlines and shortage of supplies). In comparison to rejection of as cast semis (internal rejection in the steelworks), this cost is about 60% higher.

Deep fundamental investigations, measurement technologies, process models and online control approaches were developed. Within this dissemination project, the achieved knowledge and results obtained in the previous projects in the mentioned topics will be analysed, valorised and disseminated. Also, a road map with future industrial targets and research needs will be defined.

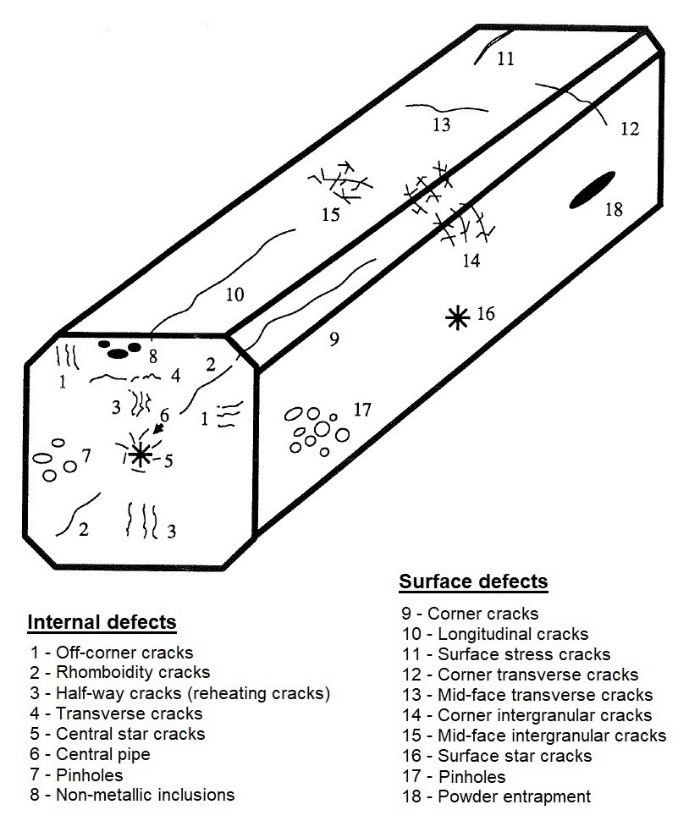

Internal defects1 – Off-corner cracks2 – Rhomboidity cracks3 – Half-way cracks (reheating cracks)4 – Transverse cracks5 – Central star cracks6 – Central pipe7 – Pinholes8 – Non-metallic inclusions | Surface defects9 – Corner cracks10 – Longitudinal cracks11 – Surface stress cracks12 – Corner transverse cracks13 – Mid-face transverse cracks14 – Corner intergranular cracks15 – Mid-face intergranular cracks16 – Surface star cracks17 – Pinholes18 – Powder entrapment |

MAIN TOPICS

Basic knowledge

Models

Process optimization

Measuring systems

On-line control systems

…